In this post I give information about generating cost listings for an innovative new item. These details is mostly for a creator or entrepreneur that features started offering an innovative brand new item and has now obtained an inquiry from a wholesaler, supplier or retail chain. This query may keep the vow of a big amount order. This new chance for possible huge volume purchase holds great vow. But, it is a two edge sword in that the possibility additionally keeps great potential dangers. This short article outlines the risks additionally the basic ideas behind creating a price quote for a possible huge amount order.

Initially the Bad News

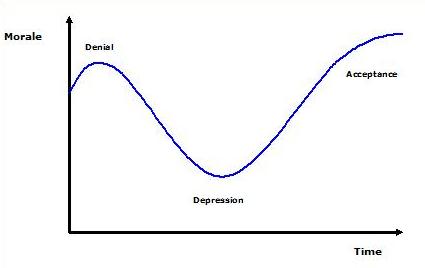

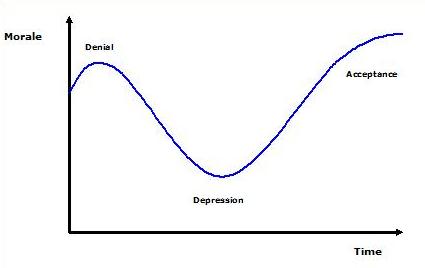

The biggest hazard is handling the money flow for a big amount order. The following biggest danger is the manufacturing difficulties associated with a huge purchase. The 2 biggest hazards frequently function together to entirely ruin a company. It is ironic that the really success associated with product seeds the failure of this business.

The issues with money movement are that repayments for stock take place many months before the income from product sales for the inventory is gotten. It is typically the outcome that 50% for the costs of inventory be paid before manufacturing starts. The various other 50% is because of as soon as the product is loaded for cargo. It can just take 45 times to produce this item and another week or therefore to load it for cargo. In the event that product is made overseas, it might probably simply take a week to clear traditions and another 2 weeks for transit. When it lands in a US interface it typically takes a week to obvious traditions. Then the item usually needs to be transported to a warehouse. This takes another week or two to arrange and move. Once the item gets towards the warehouse it requires even more time for you unload and process. This processing could include staging the product in accordance to your customer’s requirements. Eventually it takes time for you either ship the item into the consumer or arrange for it to be picked up during the warehouse.

After the product is received because of the buyer and according to the repayment terms it might possibly be another thirty day period or even more before payment. In addition to payment check may be cut from the 30th day and mailed which adds another 5-9 times into the distribution time. After that when the check is cashed the bank might add another 5 times to clear the check and post the payment to the account.

The lag between whenever the inventory expenditure is happened and profits is received from that inventory can avoid the ordering of even more stock. What generally takes place is the fact that sales take off however the inventor or business person cannot purchase even more inventories to fuel the rise. Considering that the requests are perhaps not filled in a timely way, clients cancel their particular orders and sales dry up. There are methods to invest in inventory such as very early repayment discounts, factoring, and buy order financing but each has dangers and draw backs. These methods will not be covered here.

The lag between whenever the inventory expenditure is happened and profits is received from that inventory can avoid the ordering of even more stock. What generally takes place is the fact that sales take off however the inventor or business person cannot purchase even more inventories to fuel the rise. Considering that the requests are perhaps not filled in a timely way, clients cancel their particular orders and sales dry up. There are methods to invest in inventory such as very early repayment discounts, factoring, and buy order financing but each has dangers and draw backs. These methods will not be covered here.

Another way the company can sink is related to production problems. You can be that the producer is certainly not set as much as handle huge instructions. Just like the stock funding over the purchases can’t be filled in a timely fashion and they are eventually canceled. Another issue may be quality. For an innovative new product there may be a discovering curve and in case the product involves new processes and machines this learning curve may take a while. New production equipment and processes can simply take a while to debug. Exactly what usually happens is that a huge number of terrible product is made as a result of quality issues have actually maybe not been found and settled before it is too later part of the. In this situation product sales dry up because numerous customers obtain low quality products.

Minimal Quantity Order and Vendor Packages

Packing for large requests isn’t the exact same once the list packaging. This merchant packaging generally holds several retail bundles. The wide range of retail packages that are within the seller packages is decided by business economics associated with product. When developing the requirements from the vendor package the minimal order quantity (MOQ) needs to be examined. For instance, it would likely take 15 mins to bundle and label an item for shipment. In addition, the shipping company may recharge a pick up charge or someone may prefer to provide the packaged item to your shipper. Enough time, charges, and products (packing containers and labels) all increase the expenses associated with the item. These costs must either be absorbed by business or even the customer. In either situation it adds towards the cost of this item. If the product margin is reasonable these extra prices may rate this product away from the market. Nevertheless, if the merchant package keeps 10 products while the item is shipped in products of 10 the costs connected with processing an order is distributed across 10 units instead of one. In inclusion, just one label, one package, one pickup charge or one delivery is designed for 10 products. If each unit were sent independently it would at least take 10 labels and 10 packages. Exactly the same types of cost savings happens whenever big purchases are put with all the items maker. Whenever choosing the MOQ one also needs to consider the customer requirements. The consumer may specify the MOQ based on their particular very own business economics.

The Feeling Curve

The idea behind the knowledge bend is the fact that the product regarding the expenses and purchase volume elevated for some power remains constant. As a mathematical formula it’s conveyed as:

CVn = Constant, exactly where C is the device price, V is the wide range of units ordered; n is a genuine number in the selection of 0.001 to 0.5.

What the idea suggests is the fact that the expenses per unit declines as the total wide range of products bought increases. The total units purchased are taken to imply all of the devices ever before bought. Exactly what the idea does not have is the price does perhaps not decrease permanently and has a bottom exactly where cost decrease stops. The explanations for the price decline are many. One reason is that as the product is made the process becomes much more efficient. In brief, people have actually discovered to complete the job much better. Another explanation is the fact that expenses are disseminate over bigger volumes so that the per product cost increase to cover those costs decreases. For example, if it take the same amount of strive to process an order for 10 pounds of product as it does for a 1000 pounds, the marginal rise in a lb of material because of to labor costs would be a lot much less for the 1000 lb purchase than the 10 pound purchase. Other expenses such as center, utility, etc… would similarly be dispersed over a larger wide range of units.

What the idea suggests is the fact that the expenses per unit declines as the total wide range of products bought increases. The total units purchased are taken to imply all of the devices ever before bought. Exactly what the idea does not have is the price does perhaps not decrease permanently and has a bottom exactly where cost decrease stops. The explanations for the price decline are many. One reason is that as the product is made the process becomes much more efficient. In brief, people have actually discovered to complete the job much better. Another explanation is the fact that expenses are disseminate over bigger volumes so that the per product cost increase to cover those costs decreases. For example, if it take the same amount of strive to process an order for 10 pounds of product as it does for a 1000 pounds, the marginal rise in a lb of material because of to labor costs would be a lot much less for the 1000 lb purchase than the 10 pound purchase. Other expenses such as center, utility, etc… would similarly be dispersed over a larger wide range of units.

The easiest option to utilize the Enjoy formula above will be establish the worth of this constant into the cost of one product and next experiment with different values of n. For that reason set Constant equal to C and try different values of V and n is shown below:

- C = Constant = $10

- C for a 1000 products n = 0.001;

- C(1000) = $10/1000^0.001 = $9.93

- C for a 1000 units n = 0.01

- C(1000) = $10/1000^0.01 = $9.33

A significantly better strategy is to determine the price regarding the Constant and n from manufacturing estimates. Many producers provide estimates with a cost breakdown when it comes to prices associated with the amount of this order. There is a slip to my internet site beneath the “Helpful creator Information” showing just how to estimate the values of this Constant and n from manufacturing bids. This will be certainly much better the price associated with the Constant and n are not arbitrarily assigned.

Putting It Completely to come up with a Cost Quote

Following the MOQ has already been established therefore the cost savings because of to the knowledge bend have determined this information enables you to create a price estimate for a supplier, wholesaler or retail sequence. Every various other info that impacts the margin of profit of this item should additionally be integrated. In the event  that inventory is financed through a loan, factoring, or purchase requests the expenses of obtaining the funding should also be included. Furthermore, any unique requirements of the provider, wholesaler, or retail stores that significantly increase costs or reduced margins should are additionally considered. List stores frequently require a flawed item allowance, defective packaging allowance, promotional allowances and very early repayment allowances. All those allowances are take off-the-top and lower the cost paid when it comes to item. It’s advisable to consider these deductions when generating the cost listings. The concept will be offer this item at an income.

that inventory is financed through a loan, factoring, or purchase requests the expenses of obtaining the funding should also be included. Furthermore, any unique requirements of the provider, wholesaler, or retail stores that significantly increase costs or reduced margins should are additionally considered. List stores frequently require a flawed item allowance, defective packaging allowance, promotional allowances and very early repayment allowances. All those allowances are take off-the-top and lower the cost paid when it comes to item. It’s advisable to consider these deductions when generating the cost listings. The concept will be offer this item at an income.

Finally ask the provider about the minimum and optimum measurements of the order and produce a price estimate for at least those 2 volumes. In the event that differences between the minimum and maximum volumes are significant consider producing cost estimates in action sizes that is sensible (i.e. 2000 to 5000 volume increments).